Digital Paperless Recorders

- Home

- Digital Paperless Recorders

We are Manufacturer, Supplier, Exporter of Digital Paperless Recorders and our setup is situated in Pune, Maharashtra, India.

A unique data storage feature using dot‐matrix printer provides a digital value records thus eliminating the maintenance cost involved with chart paper and pens.

Using an 80 column or 132 column standard printers’ data may be printed for a fix period of time. This feature makes it 21 CFR Complaint All the printing format and printing parameters can be programmed by front keypad.

Our Soft were which helps to remove Graphs & Print the data in tabular form helps you in analyzing the data.

- ¼ DIN size package.

- Microprocessor based accuracy.

- Alarm capabilities with relay outputs.

- 8 ch., 16 channel models.

- TABULAR/SCAN mode facilities.

- Addressable serial interface.

- Retain set up during power loss.

- Data storage for analysis using standard 80columns printer with Series Diditherm9000L.

- MountingMethod:-PanelFlush‐mounted

- (STD)Material:-AluminumANODISED

- Power:230VAC+/-10%50Hz

- Usb Pen Drive Interface

- Power Consumption : 50 Watt

- Input Signals : 4-20 mA, 0-20mA, 0-10VDC, 0-5VDC ,0-1VDC, RTD, T/Cs: J,K,R,S,N,T.

- 3.5" 5.7" TFT (640 x 480 Pixels) 7.5" TFT (640 x 480 Pixels)

- 9.2" TFT (640 x 480 Pixels)

- 15" TFT (800 x 600 Pixels).All size are Diagonally

- Burn Out Function : Equipped for T/Cs & RTD.

- Memory Capacity : 24 MB Max

- Expandable to 1000MB Max (Optional)

- Life of Backlit : 50,000 Hrs

- Operating Conditions: 0 to 50Deg C & 0 to 80% RH

- Printer Port : (Optional) Parallel Port

- Analog Input resolution : 16 Bit

- Touch Screen : Optional in 5.7" TFT (640 x 480) 7.5" TFT (640 x 480 Pixels) 9.2" TFT (640 x 480 Pixels)

- EMC Standard : Compiles with EN61326-1& CE approval(optional)

- Real Time Clock (RTC) Display On the front Screen

- No. Of inputs: 8, 16 IN CASE Of Digitherm 9000L

- Eliminates costs by removing pens, paper and maintenance associated with paper recorders & can be used in offline mode.

- Improve productivity through efficient data transfer to PC’s and spreadsheet programs.

- Optimize management of recorded information.

- Power: 230VAC +/-10% 50 Hz

- Display: Standard 3.5” Touch Screen color LCD Screen.

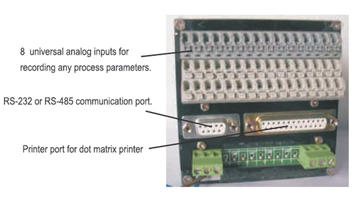

- Communication (optional): RS-2332C or RS-485 multidrop. MODBUS protocol.

- Facilities: tabular/Scanning mode, Channel skips.

- Operating temp. 0-55° C, 90% Rh Max.

- Memory: EEPROM.

- Connections: D connector with extended terminal board having screw type terminals.

- Color Change once PV Crosses the Set Value

| Input | Sffx | Range | Resolution |

| J | ‐J | ‐100 ‐1100° C | 1°C |

| K | ‐K | ‐150‐1200° C | 1°C |

| T | ‐T | ‐100 ‐250°C | 0.1°C |

| R | ‐R | Amb‐1500°C | 1°C |

| S | ‐S | Amb‐1500°C | 1°C |

| N | ‐N | ‐250 ‐ 1200°C | 1°C |

| RTD | ‐R1 | ‐200 TO +300°C | 0.1°C |

| 0‐5 VDC | ‐V | Scalable | 1 Digit |

| 0 / 4‐20 mA | ‐1 | Scalable | 1 Digit |

Relay: 2; For High / Low alarm. Optically isolated relay contact rated 230VAC @ 5A resistive

| Accuracy | +/- 0.15% F.S |

| Set point Resolution | 0.1/ 1 count (Programmable in case of 4-20mA.0 to 20Ma,0 – 10 Vdc) |

| Input sampling | 1 channels / second |

- Dairy equipments.

- Sugar Industries.

- Boilers.

- Chemical and Pharmaceutical Process Industries.

- Breweries.